What is die casting?

Die casting is a metal casting process in which molten metal is forced under high pressure into a mold cavity. It is efficient, economical and offers a broader range of shapes and components than any other manufacturing technique.

As well as producing durable, heat resistant parts with a long service life, die casting is also a high-speed process which can deliver quick and accurate results in multiple finishes.

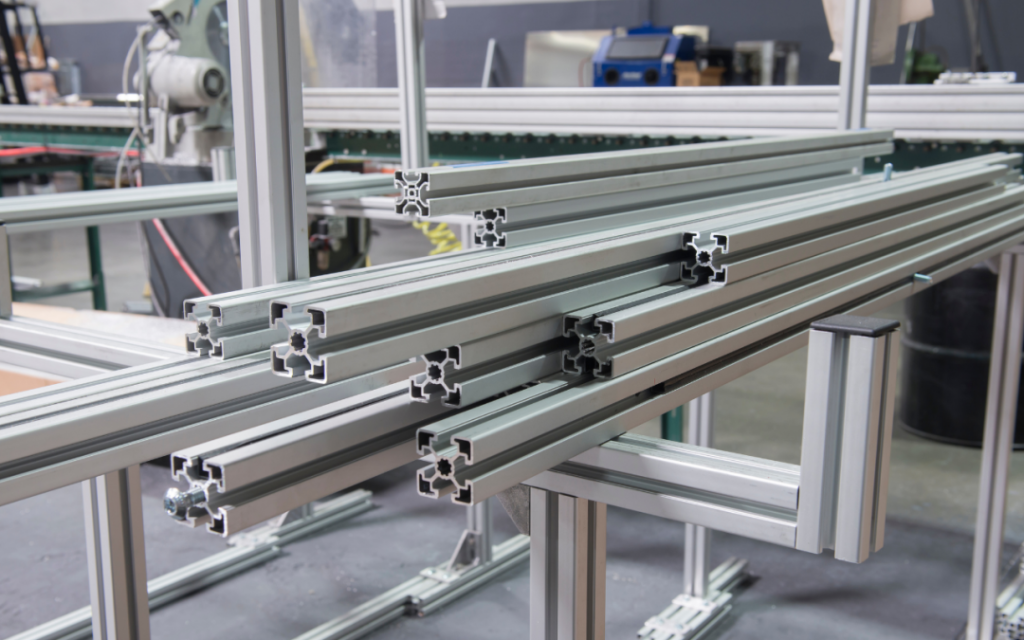

Extrusions

The manufacturing process in which the material is pushed through a die in the shape of the desired cross-section.Once the material has been pushed through the die it is then cooled with air or water to prevent warping.

This is a relatively simple process and due to the high quality of finish on the product after manufacture there is minimal need for secondary machining for finish.

Benefits to extrusions are its low cost (once tooling is complete) high volume, consistency and available to many materials.

The downsides are that the edges have to be uniform, for example you could not extrusion manufacture a pen as it narrows at one end.

For full sizing details which we provide please contact us.

Get in touch

We specialise in New Product Introduction (NPI)—from rapid prototyping to full-scale production—delivering high-quality, precision manufacturing solutions tailored to your exact requirements.

Whether you’re developing a new component, refining an existing design, seeking a benchmark quote, or simply exploring new possibilities, we’re here to help. We welcome the opportunity to collaborate and discuss how we can support your next project.

We look forward to hearing from you.